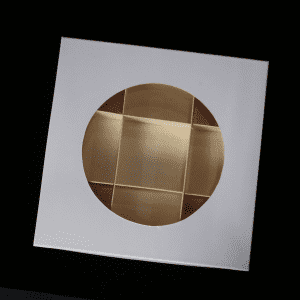

Biodegradable Compostable Hamburger Box Container

Product Parameter

| Size | 15.5*15.5*8cm |

| Weight | 10g-20 g |

| Material | Corn Starch |

| Color | Natural or Customized |

| Packing | Poly Bag and Carton |

| Logo | Customized Logo |

| MOQ | 20000 Pcs |

| Application | Home, Hotel or Restaurant |

| Sample | Availiable and Free |

Product Advantages

Thermoplastic starch currently represents the most widely used bioplastic, constituting about 50 percent of the bioplastics market.Simple starch bioplastic can be made at home by gelatinizing starch and solution casting.Pure starch is able to absorb humidity, and is thus a suitable material for the production of drug capsules by the pharmaceutical sector. However, pure starch-based bioplastic is brittle. Plasticizer such as glycerol, glycol, and sorbitol and can also be added so that the starch can also be processed thermo-plastically.The characteristics of the resulting bioplastic (also called "thermoplastic starch") can be tailored to specific needs by adjusting the amounts of these additives. Conventional polymer processing techniques can be used to process starch into bioplastic, such as extrusion, injection molding, compression molding and Biodegradable Compostable Hamburger Box Container. The properties of starch bioplastic is largely influenced by amylose/amylopectin ratio. Generally, high-amylose starch can result in better mechanical properties. However, high-amylose starch has less processiblity because of its higher gelatinization temperature and higher melt viscosity.

Starch-based bioplastics are often blended with biodegradable polyesters to produce starch/polylactic acid, starch/polycaprolactone or starch/Ecoflex (polybutylene adipate-co-terephthalate produced by BASF) blends. These blends are used for industrial applications and are also compostable. Other producers, such as Roquette, have developed other starch/polyolefin blends. These blends are not biodegradable, but have a lower carbon footprint than petroleum-based plastics used for the same applications.

Due to the origin of its raw material, Biodegradable Compostable Hamburger Box Container is cheap, abundant, and renewable.

Starch-based plastics are complex blends of starch with biodegradable or compostable plastics such as polylactic acid, polybutylene adipate terephthalate, polybutylene succinate, polycaprolactone, and polyhydroxyalkanoates. These complex blends improve water resistance as well as processing and mechanical properties.

Product Application

Biodegradable Compostable Hamburger Box Container (mostly used for packaging purposes) are made mainly from starch blended with thermoplastic polyesters to form biodegradable and compostable products. In food packaging, these Biodegradable Compostable Hamburger Box Container are seen as bakery or fruit and vegetable box. Biodegradable Compostable Hamburger Box Container are used in selective collecting of organic waste. Further, a new Biodegradable Compostable Hamburger Box Container was developed by Agricultural Research Service scientists can even be used as a bottle.

Starch-based nanocomposites have been widely studied, showing improved mechanical properties, thermal stability, moisture resistance, and gas barrier properties.