Renewable Compostable Multi-use Pulp Container

Chunkai Group focus on compostable sugarcane bagasse fiber pulp molding food packaging. Made from sugarcane a renewable resource, these packing containers are not only affordable but 100% biodegradable and Compostable. Many clients believe that is really a great eco-container option.

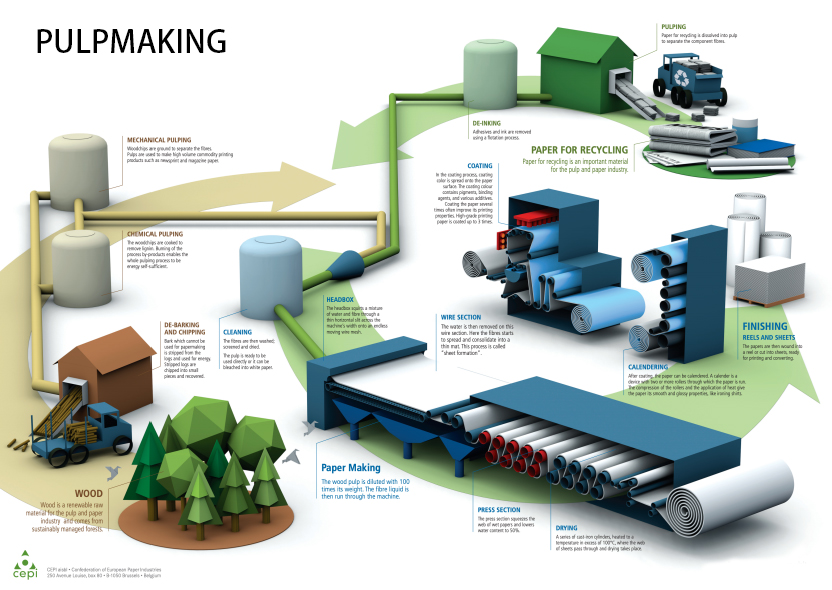

Then how to make pulp ?

To make pulp, wood is chipped and screened to create chips of the desired size and then cooked with a chemical called white liquor to produce a mixture in a pulp digester. The purpose of this stage is to release the natural glue that bonds wood fibre. The cooked pulp called brown stock pulp is washed, screened and undergoes further processing and bleaching to ensure that the final product is whiter, more absorbent and resistant. The pulp making process is fully automated, and uses state of the art equipment,Our pulps are so practical that the uses of such pulp products are very close to our daily life , You see pulp all around you every day in all ways .